“Discover advanced fuel level sensors for industrial boilers—enhancing efficiency, accuracy, and operational safety.”

Fuel level sensor

Revolutionizing Fuel Monitoring Systems

INTRODUCTION

Fuel level sensors are innovative devices that play a crucial role in accurately measuring and monitoring the amount of fuel present in various types of vehicles, machinery, and storage tanks. These sensors have significantly transformed the way we manage fuel resources, enabling efficient fuel consumption, preventing fuel theft, and contributing to overall cost savings. In this article, we delve into the intricacies of fuel level sensors, their types, applications, and the benefits they bring to different industries.

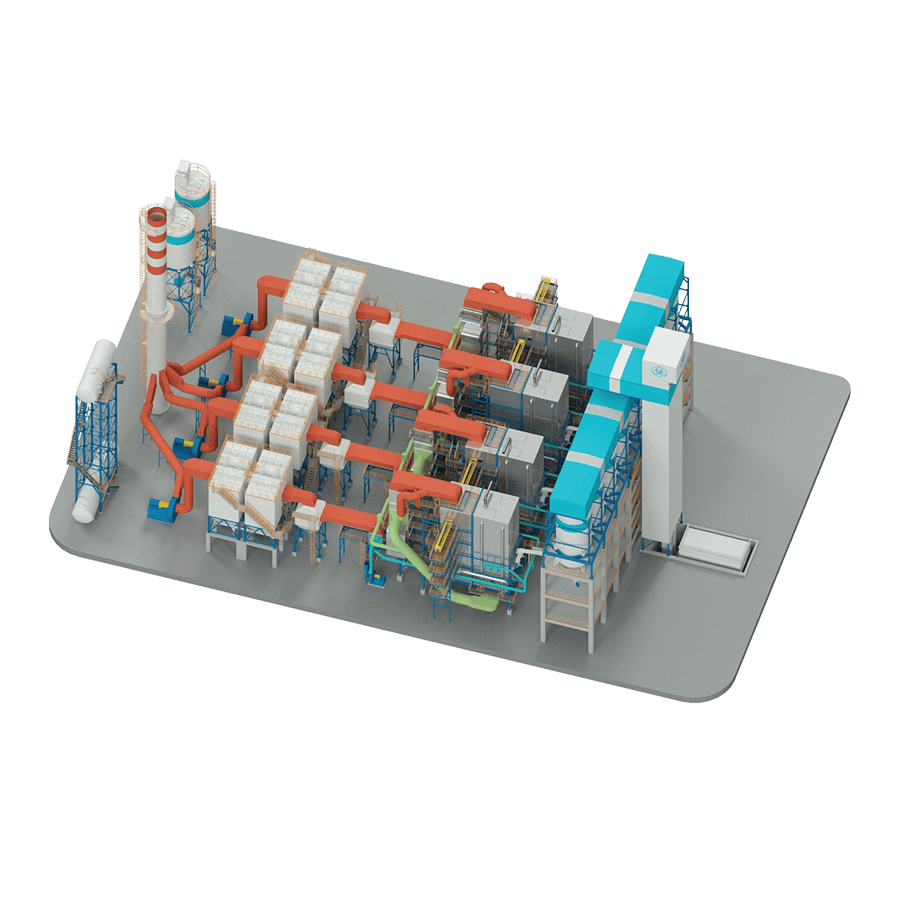

Figure – Fuel level sensors

1- Introduction to Fuel Level Sensors

Fuel level sensors, also known as fuel gauges or fuel level transmitters, are electronic devices designed to provide real-time information about the quantity of fuel in a given container. Their primary objective is to offer accurate and reliable data to users, enabling them to make informed decisions regarding fuel usage and management. By employing advanced technology and engineering principles, fuel level sensors have become an integral part of modern fuel monitoring systems.

2- Types of Fuel Level Sensors

There are several types of fuel level sensors available, each employing different principles to measure fuel levels. Capacitance-based sensors operate by measuring the change in capacitance as fuel comes into contact with the sensor. Ultrasonic sensors utilize sound waves to determine the distance between the sensor and the fuel surface. Resistive sensors, on the other hand, change their resistance based on the fuel level, and this change is then converted into a corresponding fuel level reading. Additionally, magnetostrictive sensors use the principles of magnetostriction to accurately gauge the fuel level.

3- Applications and Industries

Fuel level sensors find applications across a wide range of industries and sectors. In the automotive industry, these sensors are integrated into vehicles to provide drivers with real-time information about their fuel levels, ensuring they can plan their refueling stops efficiently. Construction and agriculture sectors utilize fuel level sensors to monitor heavy machinery and equipment, preventing unexpected fuel shortages and optimizing operations. Furthermore, fuel storage tanks in industries such as manufacturing, logistics, and energy generation rely on these sensors to manage inventory and streamline fuel supply chains.

4- Benefits of Fuel Level Sensors

The implementation of fuel level sensors offers numerous advantages that enhance operational efficiency and reduce costs. With accurate fuel level data at their fingertips, businesses can optimize fuel consumption, leading to significant fuel savings over time. By preventing instances of fuel theft and unauthorized usage, these sensors contribute to increased security and financial stability. Moreover, proactive maintenance becomes possible as fluctuations in fuel levels can be detected early, preventing potential equipment damage and downtimes.

5- Improved Fuel Management

Fuel level sensors enable precise monitoring of fuel consumption patterns, allowing businesses to identify trends and anomalies. This data-driven approach assists in devising strategies to reduce wastage and improve overall fuel efficiency. Fleet management companies, for instance, can analyze the data collected from sensors to identify drivers who may need additional training in fuel-efficient driving practices. This not only leads to cost savings but also contributes to environmental conservation by reducing carbon emissions.

6- Enhanced Operational Planning

Fuel availability can significantly impact operational planning in industries like agriculture and construction, where machinery heavily relies on fuel. Fuel level sensors ensure that managers are aware of fuel levels at all times, allowing them to schedule refueling activities without disrupting ongoing operations. This proactive approach minimizes unexpected downtimes due to fuel shortages and maximizes productivity.

7- Environmental Sustainability

Fuel level sensors indirectly promote environmental sustainability by fostering efficient fuel usage. When businesses reduce fuel wastage through accurate monitoring, the overall demand for fuel decreases. This, in turn, contributes to lower fuel production and consumption, subsequently reducing the carbon footprint associated with fuel-related activities.

CONCLUSION

Fuel level sensors have revolutionized the way we manage and utilize fuel resources across various industries. Through accurate and real-time monitoring, these sensors empower businesses and individuals to optimize fuel consumption, enhance operational planning, and contribute to environmental conservation. With continuous advancements in sensor technology, we can expect even more sophisticated and precise fuel level sensors to emerge, further improving fuel management systems worldwide. As industries continue to recognize the value of efficient fuel usage, fuel level sensors stand as a testament to innovation driving positive change.

(Vn-Industry.)

Home page: https://vn-industry.com/