“Selecting the optimal fuel in a cogeneration system enhances efficiency, reduces costs, minimizes emissions, and ensures sustainable, environmentally friendly operation.”

How to choose the optimal fuel in a cogeneration system (CHP)?

Energy Saving and Efficiency

INTRODUCTION

The optimal fuel selection in a cogeneration system (CHP) plays an important role in improving efficiency, reducing operating costs, and protecting the environment. The system using the right fuel will save energy, reduce greenhouse gas emissions, and prolong the life of the equipment. Therefore, it is necessary to carefully consider important criteria to achieve the best efficiency.

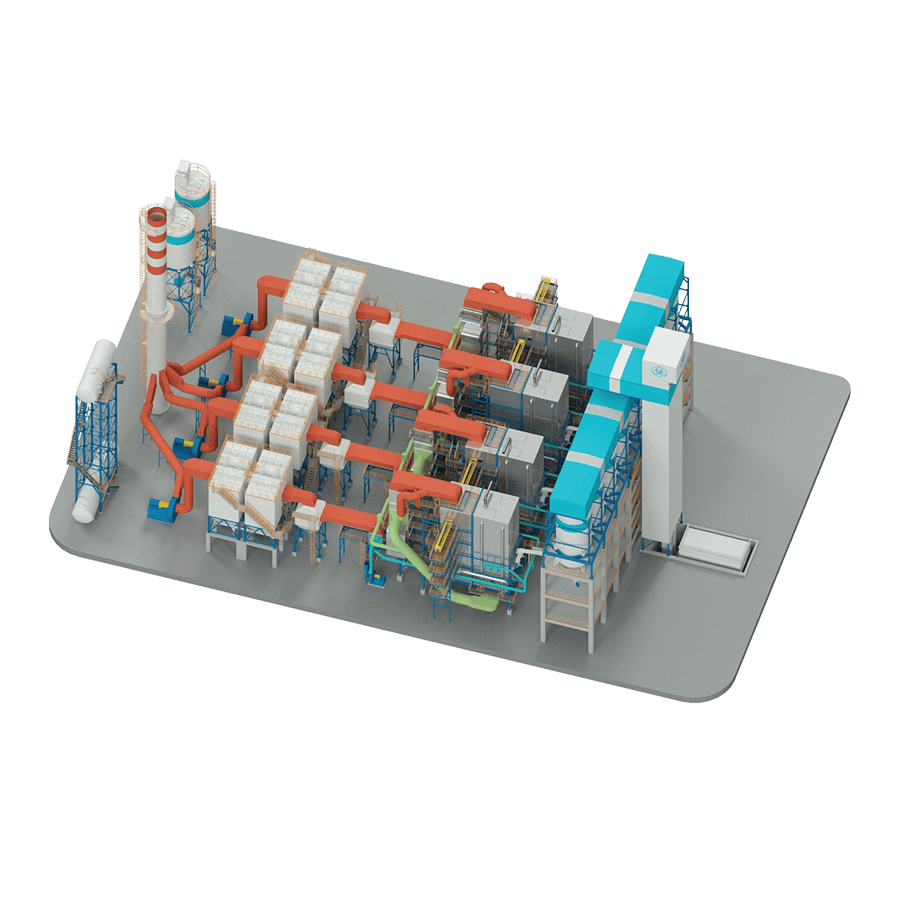

Figure 1 – Biomass is medium heat but clean

Figure 2 – Coal has a high calorific value but is polluting

Key criteria for selecting the optimal fuel in a cogeneration system

Energy efficiency

A fuel with high conversion efficiency is essential. For example, natural gas is preferred due to its clean combustion and superior efficiency. In addition, biogas is a sustainable choice when it comes to reducing dependence on fossil fuels.

System compatibility

Not all fuels are suitable for CHP systems. Therefore, you should check the compatibility between the equipment and the fuel, such as natural gas, diesel or biogas, to achieve maximum efficiency.

Environmental impact and supporting policies

Today, clean fuels such as biogas or hydrogen are preferred due to their reduced CO₂ emissions. Countries that promote renewable energy in particular often provide price support. In addition, they apply tax incentives.

Costs and supply

A stable and affordable fuel source helps ensure the sustainability of the system in the long term. Access to fuel on-site also has a major impact on operational efficiency.

HOW TO CHOOSE FUEL

Based on the technology used

Steam turbine: Requires a heat source from the boiler, so the selected fuel must ensure the ability to provide large heat.

- Coal, coal dust: ideal fuel for high-pressure boilers, large steam output.

- Biomass, waste: suitable fuel for specialized boilers (fluidized bed boilers/waste incinerators)

For example, Paper mills in Vietnam use bagasse (biomass) as fuel for steam turbines, taking advantage of available waste sources.

Gas turbine: Requires gas to rotate the turbine directly, generating heat and electricity at the same time.

- Natural gas (NG): most suitable for gas turbines because of high efficiency and clean combustion.

- Biogas: used on a small scale, reducing carbon emissions.

For example, Power plants in the ASEAN region often use natural gas from domestic gas sources.

Based on geographical area and available fuel source

Local fuel source:

-

- Coal: Suitable in areas rich in coal resources, such as Quang Ninh.

- Biomass: Areas with many agricultural by-products, such as wood, rice husks, and bagasse (Mekong Delta) are ideal.

- Urban waste: Densely populated areas such as Ho Chi Minh City or Hanoi are suitable for waste-to-energy incineration systems.

- Natural gas: Countries with natural gas mines (Qatar, Australia) will deploy gas turbine systems.

For example, Tay Ninh Sugar Factory uses bagasse as fuel instead of commercial fuel.

Based on steam and electricity production needs

Prioritize steam:

- When the heat demand is high, cheap fuels such as biomass or waste will be more effective.

- For example, Food processing plants use cheap and stable fuels such as biomass or waste.

Priority for electricity:

- When large power generation is required, gas turbines with natural gas or high-quality coal will be the optimal choice.

- For example, Gas power plants in Malaysia use natural gas to optimize efficiency.

Based on environmental factors and policies

Emissions and environmental standards:

Fuel selection must comply with local environmental standards

- Coal, coal dust: High emissions, requiring exhaust gas treatment systems such as dust filtration, SOx, and NOx removal. These fuels are often suitable in areas with less stringent environmental standards.

- Biomass, natural gas: Low emissions, preferred in areas with strict environmental standards or where the use of renewable energy is encouraged.

Renewable Energy Support Policy

- In countries that focus on renewable energy development, fuel sources such as biomass, biogas, or waste are often prioritized thanks to price support or tax incentives.

- For example, in Germany, the feed-in tariff policy strongly promoted the use of biomass and biogas, bringing economic advantages and environmental protection.

Figure 6 – Germany has subsidized biomass fuel through the feed-in tariff policy for decades

Figure 6 – Germany has subsidized biomass fuel through the feed-in tariff policy for decades

Based on cost and economic efficiency

Fuel cost:

- Choosing cheap, readily available fuel helps reduce operating costs.

- For example, plants near coal sources will use this fuel because the cost is much lower than natural gas.

Fuel efficiency:

- High-heating fuels such as natural gas are suitable if high efficiency is required.

- Cheap fuels such as waste or biomass are more suitable when investment and operating costs are important factors.

CONCLUSION

Optimal fuel in the following specific cases:

| Case | Technology | Suitable fuels | Examples |

|---|---|---|---|

| Near coal mines, large power generation | Steam Turbine | Coal, coal dust | Quang Ninh Thermal Power Plant (Vietnam). |

| Near agricultural areas, large steam production | Steam Turbine | Biomass, bagasse, rice husk | Thanh Cong Sugar Factory in Dong Nai. |

| Urban areas, waste treatment | Turbine hơi | Urban waste | Thanh Cong Sugar Factory in Dong Nai. |

| Near natural gas sources, large power generation | Gas Turbine | Natural gas, LPG | Can Tho Waste Incineration Plant. |

| Areas with renewable support policies | Steam Turbine or Gas Turbine | Biomass, biogas | Biomass Plant in Germany or Mekong Delta, Vietnam. |

Choosing the optimal fuel for a cogeneration system requires careful consideration of factors such as energy efficiency, technology, cost, and environment. By carefully analyzing these criteria, you can optimize system performance, ensure sustainable operation, and minimize negative environmental impacts.

-> To improve the performance of a cogeneration system, see the article.