“Vietnam builds its first LNG power plant to ensure energy security, cut emissions, attract foreign investment, and support sustainable growth.”

Vietnam builds its first LNG power plant

Ensuring national energy security by 2025

INTRODUCTION

Reasons to Build an LNG Power Plant in Vietnam

Vietnam is actively developing clean energy sources and diversifying its electricity supply. The construction of the first LNG power plant marks a significant step in this strategy, contributing to national energy security while reducing environmental impacts from traditional energy sources.

LNG Power Plant – A Technological and Sustainable Advancement

Vietnam’s first LNG power plant will play a crucial role in supplying electricity to the national grid once completed. Its expected capacity will meet increasing demand, especially in key economic regions.

Using LNG, a cleaner fuel than coal, will significantly reduce greenhouse gas emissions, helping to protect the environment. The plant is designed with advanced technology to ensure high efficiency and stable operation, enhancing the reliability of the electricity supply.

Economic and Social Benefits, Attracting Investments

Besides energy benefits, the project will create numerous job opportunities for local workers. During both construction and operation, the plant will require a highly skilled workforce, thereby improving human resource quality in the energy sector.

Additionally, investments in infrastructure related to the project will boost the development of supporting industries, contributing to overall economic growth. The presence of the LNG power plant will also attract foreign investments, helping Vietnam integrate more deeply into the global economy.

LOCATION AND SCALE OF THE LNG POWER PLANT PROJECT

Vietnam’s First LNG Power Plant

Location:

The Nhon Trach 3 power plant is being built in the Ong Keo Industrial Park, Phuoc Khanh Commune, Nhon Trach District, Dong Nai Province. This location is near major seaports, facilitating the import of liquefied natural gas (LNG), and has a strong electrical grid, ensuring effective connectivity to the national grid.

Scale:

The Nhon Trach 3 and 4 power plant projects have a total investment of approximately $1.4 billion (equivalent to VND 35.434 trillion), with a designed capacity of 1,500–1,624 megawatts. Once operational, the two plants are expected to supply 9–12 billion kWh of electricity annually to the national grid, meeting Vietnam’s growing energy demand.

Choosing Dong Nai as the location optimizes logistics for LNG imports, leverages existing infrastructure, and minimizes environmental and social impacts. The involvement of international investors and advanced technology adoption further enhances the project’s scale and modernization.

Nhon Trach 3 officially connected to the national power grid on February 5, 2025, marking a milestone in Vietnam’s energy sector. Nhon Trach 4 is expected to commence operations in October this year, continuing to contribute to energy security and sustainable development.

TECHNOLOGY AND EQUIPMENT USED IN THE LNG POWER PLANT

LNG power plants utilize liquefied natural gas (LNG) as fuel for electricity generation, integrating advanced technologies and equipment to ensure high efficiency and minimize environmental impact. Below is an overview of key technologies and equipment used in these plants:

Combined Cycle Gas Turbine (CCGT) Technology

CCGT technology, widely used in LNG power plants, combines gas turbines and steam turbines to optimize efficiency. The process includes:

- LNG Combustion: LNG is re-gasified and burned in gas turbines, generating mechanical energy to drive electricity generators.

- Heat Recovery: Hot exhaust gases from gas turbines pass through Heat Recovery Steam Generators (HRSG) to produce steam.

- Steam Turbines: The steam is used to power steam turbines, generating additional electricity and improving overall plant efficiency.

Reusing heat from exhaust gases reduces energy loss and enhances efficiency compared to traditional power generation methods.

LNG Storage and Regasification System

Before use, LNG is stored in specialized tanks at extremely low temperatures (-162°C). When needed, it undergoes regasification through vaporizers and is directed into the combustion system. The process involves:

- LNG Storage Tanks: Designed to withstand extreme temperatures and high pressure, ensuring safe storage.

- Regasification System: Uses heat exchangers to convert LNG from liquid to gas.

- Specialized Pipelines and Valves: Ensure safe and efficient LNG transportation and distribution.

These components ensure the safe and efficient handling of LNG throughout the process.

Control and Monitoring Systems

LNG power plants are equipped with modern automation and monitoring systems to ensure safe and efficient operation, including:

- Distributed Control System (DCS): Manages and controls plant processes.

- Supervisory Control and Data Acquisition (SCADA): Monitors operational parameters and detects potential issues.

- Safety Instrumented System (SIS): Automatically shuts down or adjusts operations when unsafe conditions are detected.

Integrating these systems optimizes efficiency and ensures operational safety.

Emission Reduction Technologies

To minimize environmental impact, LNG power plants implement emission reduction technologies such as:

- NOx Reduction Systems: Utilizing low-temperature combustion or catalysts to reduce nitrogen oxide emissions.

- Dust and SOx Filtration Systems: Removing dust particles and sulfur oxides from exhaust gases before release.

By adopting these technologies, LNG power plants emit significantly fewer greenhouse gases than coal-fired power plants, contributing to environmental protection.

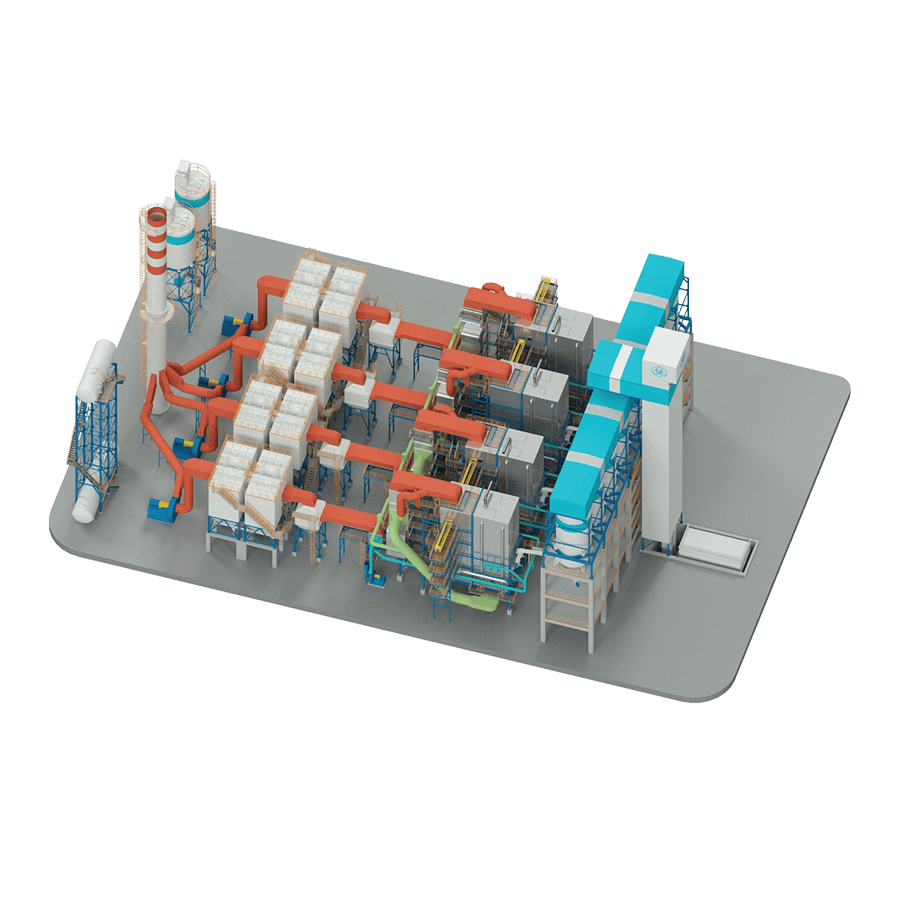

Figure 3: Vietnam’s First LNG Power Plant (Dong Nai)

LNG SUPPLY SOURCES

The Nhon Trach 3 LNG power plant, Vietnam’s first, relies on imported liquefied natural gas (LNG) as its primary fuel.

Vietnam Gas Corporation (PV GAS) is the country’s first and currently the only entity importing LNG. PV GAS owns LNG storage and regasification infrastructure to supply various consumers, including power plants.

Specifically, PV GAS has developed and operates the Thi Vai LNG Terminal, a critical facility for importing and supplying LNG to power projects like Nhon Trach 3. This ensures a stable and continuous fuel supply for plant operations.

Additionally, Vietnam is developing further LNG infrastructure to meet its growing energy needs. For example, the Cai Mep LNG Terminal is under construction and will soon become operational, enhancing the country’s LNG import capacity.

Developing LNG import infrastructure is vital for ensuring energy security and promoting clean energy use in Vietnam.

Figure 4: LNG Fuel

ECONOMIC AND SOCIAL IMPACTS OF LNG POWER PLANTS

Developing LNG power plants in Vietnam brings multiple economic and social benefits:

Ensuring Energy Security

Stable Electricity Supply: Using LNG diversifies energy sources, reduces reliance on coal and oil, and ensures a continuous electricity supply.

Environmental Protection

Lower Emissions: LNG power generation emits 45% less CO₂ than coal and 30% less than oil combustion, while reducing NOx emissions by up to 90%, contributing to cleaner air and public health.

Boosting Local Economy

- Job Creation: The construction and operation of LNG power plants create employment opportunities, improving income and living standards.

- Infrastructure Development: Investments in LNG terminals, storage, and power transmission networks drive regional economic growth.

Attracting Foreign Investment

Investor Appeal: Large-scale LNG projects with modern technology attract international investors, boosting economic growth and global integration.

To maximize economic and social benefits, Vietnam must implement rational electricity pricing policies, develop integrated infrastructure, and ensure a stable LNG supply.

Figure 5: Vietnam’s First LNG Power Plant (Dong Nai)

ENVIRONMENTAL ISSUES AND SOLUTIONS

Liquefied natural gas (LNG) power plants are highly regarded for their efficiency and ability to reduce emissions compared to traditional energy sources. However, their construction and operation still pose several environmental concerns that need to be addressed:

Greenhouse Gas Emissions

Although LNG emits less CO₂ than coal and oil, the extraction, transportation, and liquefaction of natural gas can lead to methane (CH₄) leaks— a greenhouse gas with a much stronger impact than CO₂.

Solutions:

- Implement modern technology to monitor and minimize methane leaks across the entire LNG supply chain.

- Use efficient equipment and operational processes to optimize combustion and reduce emissions.

Impact on Marine Ecosystems

The construction of infrastructure such as receiving terminals, LNG storage tanks, and gas pipelines can affect marine environments, particularly during dredging and material disposal.

Solutions:

- Conduct a detailed environmental impact assessment (EIA) before project implementation to identify and mitigate negative effects.

- Apply mitigation measures, such as using modern dredging equipment, adhering to approved dredging boundaries, and strictly managing material disposal.

Water Usage and Thermal Pollution

LNG power plants require large amounts of water for cooling systems, potentially leading to thermal pollution and impacting local water sources.

Solutions:

- Implement recirculating cooling systems to reduce water consumption and minimize thermal pollution.

- Monitor wastewater quality and comply with discharge regulations to protect water sources.

Noise and Vibrations

Power plant operations can generate noise and vibrations that affect surrounding communities.

Solutions:

- Design and construct noise reduction measures, such as using soundproof materials and optimizing equipment layout.

- Establish buffer zones and maintain safe distances between the plant and residential areas.

Implementing these solutions will help minimize the environmental impact of LNG power plants while ensuring sustainable development and environmental protection.

COMPARISON WITH OTHER POWER PLANTS IN VIETNAM

Vietnam currently operates various types of power plants, including coal-fired, hydropower, wind, solar, and, more recently, LNG power plants. Below is a comparison of LNG power plants with other types of power plants in Vietnam:

1. Compared to Coal-Fired Power Plants

- Emissions and Environment: LNG power plants emit approximately 45% less carbon than coal-fired plants and significantly reduce pollutants such as NOx and SOx, contributing to environmental and public health protection.

- Efficiency and Cost: Although the initial investment cost for LNG power plants may be higher, their operational efficiency is generally superior to coal-fired plants. However, imported LNG prices can fluctuate, affecting electricity production costs.

2. Compared to Hydropower Plants

- Dependence on Natural Conditions: Hydropower relies on rainfall and hydrological conditions, causing fluctuations in power generation. In contrast, LNG power plants can operate more consistently if a stable LNG supply is maintained.

- Environmental Impact: Hydropower can impact ecosystems and surrounding communities due to dam and reservoir construction. LNG power plants have fewer environmental impacts during construction and operation.

3. Compared to Wind and Solar Power Plants

- Power Supply Stability: Wind and solar power depend on weather conditions and time of day, leading to instability in the electricity supply. LNG power plants can provide continuous power and easily adjust capacity.

- Emissions: Wind and solar power are renewable energy sources with zero greenhouse gas emissions during operation, whereas LNG power plants still generate emissions, albeit lower than coal-fired plants.

LNG power plants offer advantages in emission reduction and stable electricity supply. However, reliance on imported LNG and price fluctuations pose challenges. Choosing the appropriate power generation method requires consideration of environmental, economic, and national energy security factors.

(Vn-Industry.)

Home page: https://vn-industry.com/