Essential Heavy Industrial Equipment List Across 10 Core Industries

Introduction

As Asia and the global economy undergo rapid industrial expansion, understanding the essential heavy industrial equipment for each sector is critical to optimize investment, improve operational efficiency, and reduce maintenance costs. This article presents a comprehensive overview of must-have equipment by sector, including functions and key specifications.

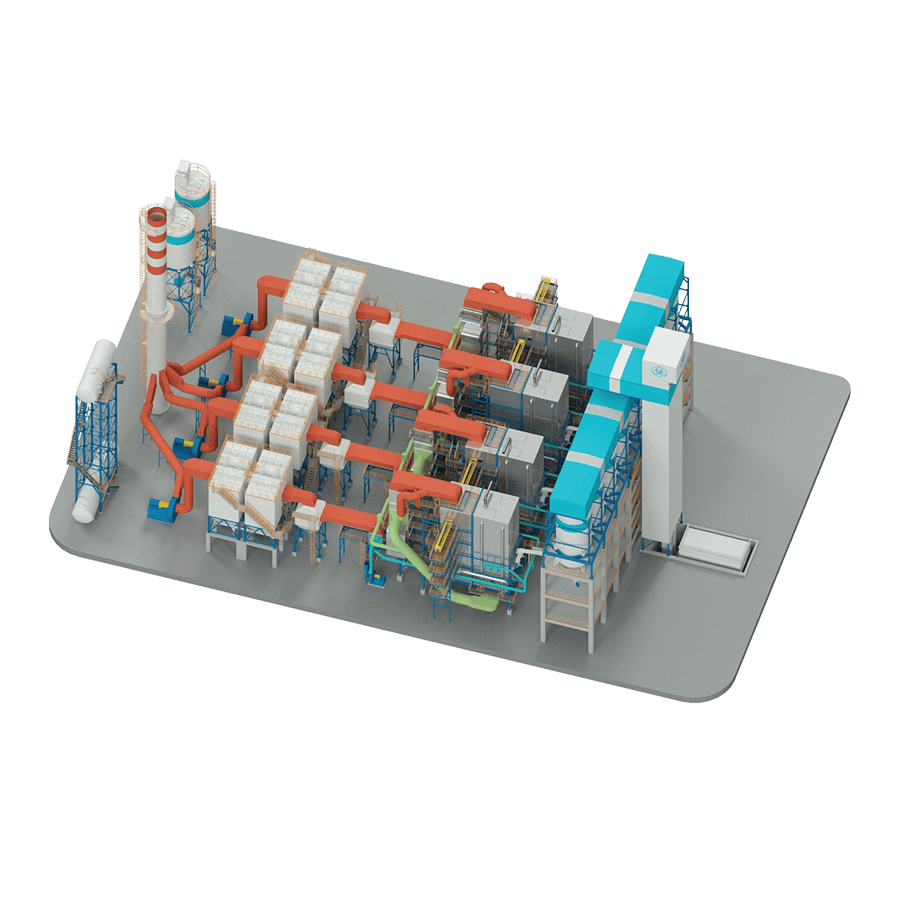

Figure 1: Heavy industrial equipment

Figure 1: Heavy industrial equipment

1. Cement Industry

- Rotary kiln for clinker

- Raw mill (vertical roller mill, ball mill)

- Packaging units & conveyor belts

- Industrial dust fans & filtration systems

- Waste heat recovery boiler (WHR)

Example: SCG Cement invested in an 18 MW WHR system at its Saraburi plant in Thailand.

2. Steel & Ferrous Metals Industry

- Electric arc furnace (EAF)

- Induction furnace

- Continuous casting machine

- Hot & cold rolling mills

- Gas treatment systems (CO, NOₓ, SOₓ)

3. Aluminum & Non-Ferrous Metallurgy

- Hall-Héroult electrolytic cells

- Ore refining units

- Metal melting furnaces

- Thermal recovery systems

- Aluminum extrusion press

4. Chemical & Petrochemical Industry

- Reactor towers

- Heat exchangers

- Specialty chemical tanks

- Air compressors, vacuum pumps

- Heat-supply boilers with automation

5. Pulp & Paper Industry

- Pulper machines

- Fourdrinier paper machines

- Deinking & flotation systems

- Biomass-fired industrial boilers

- Single/multi-cylinder dryers

6. Textile Industry

- Weaving machines

- Dyeing, drying, and finishing equipment

- Mini or fluidized-bed boilers

- Textile wastewater treatment systems

- Air compressors for workshop use

7. Food Processing Industry

- Heat-supply & sterilization boiler systems

- Processing machines: grinding, mixing, and sterilizing

- Heat dryers & steam chambers

- Industrial refrigeration systems

- Combined Heat & Power (CHP) systems

Example: Nestlé Vietnam uses a 20 t/h biomass boiler, cutting ~50,000 t of CO₂ annually.

8. Mining Industry

- Drilling rigs & hydraulic excavators

- Crushers, grinders, and screening machines

- Long-distance belt conveyors

- Flotation machines

- High-capacity dump trucks

9. Power Generation Industry

- Circulating fluidized bed (CFB) boilers

- Steam and gas turbines

- DCS/SCADA control systems

- Large-scale generators (100–1000 MWe)

- Cooling towers & emission scrubbers

Figure 2: Heavy industrial equipment

Figure 2: Heavy industrial equipment

10. Water & Environmental Treatment

- Biological reactors (UASB, SBR)

- Sludge separators & RO membrane systems

- UV sterilization systems

- High-capacity water pumps

- Air/wastewater monitoring devices

Strategic Role of a Complete Equipment List

A well-maintained heavy equipment list is crucial for:

- Investors: Estimating CapEx during new plant construction or upgrades

- Consultants & Designers: Developing accurate P&ID diagrams and selecting efficient equipment

- O&M Teams: Creating scheduled maintenance plans for critical systems

Modernization Through Technology

The trend is toward digitizing and automating plant equipment for greater precision, energy savings, and emission reductions. Many factories are replacing outdated high-capacity systems with high-efficiency equipment while integrating ISO 50001 energy management and CHP technologies.

Conclusion

Understanding the essential industrial equipment for each sector is a vital first step in any project, be it plant expansion or energy transition. In today’s tech-driven and ESG-conscious environment, equipment selection must go beyond capacity—it must support fuel efficiency and emissions reduction to stay competitive and compliant.

(Vn-Industry.)

Home page: https://vn-industry.com/